What is a VFD and why is it used?

A Variable Frequency Drive (VFD) is an electronic device used to control the speed and torque of an AC motor by varying the frequency and voltage of its power supply. VFDs are essential in industrial applications for energy savings, precise motor control, and extending equipment life. They enable soft starting, speed variation, and reduced mechanical stress. While DC drives were historically used for variable speed control, they require more maintenance due to brushes and commutators. In contrast, AC motors with VFDs are more efficient, reliable, and cost-effective, making them the preferred choice in modern industrial systems over traditional DC drives.

Industrial Application

Our Industrial Applications:

HVAC Systems:

Our VFDs are used in the following HVAC applications:

- Chiller Compressors

- Cooling Tower Fans

- Air Handling Units (AHU)

- Fans Pumps (Chilled Water Pumps, Condenser Water Pumps, Hot Water Pumps)

- Boiler Feed Pumps Exhaust Fans & Ventilation Fans

- Cooling Coils

- Heat Exchanger

- Circulation Pumps

- Variable Refrigerant Flow (VRF/VRV) Compressor

Cement Industry:

Our VFDs are used in the following Cement industry applications:

- Crushers (Jaw, Cone, Impact)

- Raw mill and Cement Mill Drives

- Kiln Drives

- Induced Draft (ID), Forced Draft (FD), and Primary Air (PA) Fans

- Conveyors and Feeders

- Cooling Fans and Pumps

- Baghouse and Dust Collector Fans

Cement Industry:

Our VFDs are used in the following Cement industry applications:

- Crushers (Jaw, Cone, Impact)

- Raw mill and Cement Mill Drives

- Kiln Drives

- Induced Draft (ID), Forced Draft (FD), and Primary Air (PA) Fans

- Conveyors and Feeders

- Cooling Fans and Pumps

- Baghouse and Dust Collector Fans

Cranes and Hoists:

Our VFDs are used in the following cranes and hoists applications:

- Hoisting (Lifting Mechanism)

- Trolley Travel (Cross Travel)

- Long Travel (Bridge Travel)

- Slewing Motion (in Jib or Tower Cranes)

- Luffing Mechanism (Boom Angle Adjustment)

- Braking and Energy Dissipation

Solar Plants:

Our VFDs are used in the following solar applications:

- Solar Tracker Motors (Single- or Dual-Axis)

- Cooling Water Pumps (for Solar Thermal Plants)

- Dust Cleaning Systems / Robotic Panel Cleaning

- Circulation Pumps (Molten Salt or Heat Transfer Fluids)

- Ventilation and Cooling Fans (Inverters or Battery Rooms)

- Auxiliary Systems (Hydraulic Drives, Feed Systems, etc.)

Solar Plants:

Our VFDs are used in the following solar applications:

- Solar Tracker Motors (Single- or Dual-Axis)

- Cooling Water Pumps (for Solar Thermal Plants)

- Dust Cleaning Systems / Robotic Panel Cleaning

- Circulation Pumps (Molten Salt or Heat Transfer Fluids)

- Ventilation and Cooling Fans (Inverters or Battery Rooms)

- Auxiliary Systems (Hydraulic Drives, Feed Systems, etc.)

Paper and Pulp Industry:

Our VFDs are used in the following paper and pulp industry applications:

- Pumps and Fans

- Paper Machine Drives

- Refiners and Crushers

- Dryers and Calenders

- Conveyors and Material Handling Systems

Textile Mills

Our VFDs are used in the following textile mill applications:

- Spinning Machines

- Weaving Looms

- Dyeing and Finishing Machines

- Air Handling and Ventilation Systems

- Material Handling Systems

Textile Mills

Our VFDs are used in the following textile mill applications:

- Spinning Machines

- Weaving Looms

- Dyeing and Finishing Machines

- Air Handling and Ventilation Systems

- Material Handling Systems

Kitchen Hoods

In kitchen hood applications, VFDs regulate fan speed based on ventilation demand, optimizing airflow, reducing energy consumption, and minimizing noise levels for efficient and adaptable exhaust control.

Our VFDs are used in the following kitchen hood applications:

- Exhaust Fans

- Supply Air Fans

- Variable Air Volume (VAV) Systems

Wire Drawing Machines

In wire drawing applications, VFDs provide precise speed and torque control to maintain consistent wire tension and diameter, enhancing product quality and reducing mechanical stress under varying load conditions.

Our VFDs are used in the following wire drawing machine applications:

- Payoff and Take-up Drives

- Drawing Machines

- Capstan Drives

Wire Drawing Machines

In wire drawing applications, VFDs provide precise speed and torque control to maintain consistent wire tension and diameter, enhancing product quality and reducing mechanical stress under varying load conditions.

Our VFDs are used in the following wire drawing machine applications:

- Payoff and Take-up Drives

- Drawing Machines

- Capstan Drives

Sugar Industry

In the sugar industry, VFDs optimize motor performance by adapting speed and torque to fluctuating loads, ensuring energy-efficient operation, minimizing mechanical stress, and maximizing equipment uptime in demanding production environments.

Our VFDs are used in the following sugar industry applications:

- Cane Crushers and Mills

- Juice Pumps and Conveyors

- Vacuum Pumps and Evaporators

- Boiler Feed Pumps

- Bagasse Handling Systems

Water and Wastewater Treatment

In sugar industry water and wastewater treatment, VFDs optimize motor speed to efficiently handle variable flow rates, reducing energy consumption and minimizing mechanical wear for reliable operation.

Our VFDs are used in the following water and wastewater treatment applications:

- Raw Water Pumps

- Aeration Blowers

- Wastewater Pumps

- Sludge Handling Equipment

Water and Wastewater Treatment

In sugar industry water and wastewater treatment, VFDs optimize motor speed to efficiently handle variable flow rates, reducing energy consumption and minimizing mechanical wear for reliable operation.

Our VFDs are used in the following water and wastewater treatment applications:

- Raw Water Pumps

- Aeration Blowers

- Wastewater Pumps

- Sludge Handling Equipment

Mining and Stone Industry

In the mining and stone industry, VFDs provide precise speed and torque control to handle heavy-duty, variable-load conditions efficiently, enhancing energy savings, equipment protection, and operational reliability.

Our VFDs are used in the following mining and stone industry applications:

- Crushers (Jaw, Cone, Impact)

- Conveyors (Belt, Screw, Chain)

- Ball Mills and Grinding Mills

- Ventilation Fans

- Dewatering Pumps

- Screens and Feeders

Rice Mills

In rice mills, VFDs enable precise motor speed control to handle variable loads, ensuring consistent processing, reduced energy consumption, and minimized mechanical wear for improved operational efficiency.

Our VFDs are used in the following rice mill applications:

- Paddy Separator and Dehusker Machines

- Elevators and Conveyors

- Polishing and Whitening Machines

- Blowers and Aspiration Systems

- Grading and Sorting Machines

Rice Mills

In rice mills, VFDs enable precise motor speed control to handle variable loads, ensuring consistent processing, reduced energy consumption, and minimized mechanical wear for improved operational efficiency.

Our VFDs are used in the following rice mill applications:

- Paddy Separator and Dehusker Machines

- Elevators and Conveyors

- Polishing and Whitening Machines

- Blowers and Aspiration Systems

- Grading and Sorting Machines

Poultry

In the poultry industry, VFDs enable precise control of motor speed to optimize ventilation, feeding, and waste handling systems, enhancing energy efficiency, animal comfort, and equipment longevity under varying load conditions.

Our VFDs are used in the following poultry applications:

- Ventilation Fans

- Feeding Systems

- Water Supply Pumps

- Waste Removal Conveyors

- Hatchery and Incubation Systems (Air Handling Units)

Machine Tools

In machine tools, VFDs provide precise motor speed and torque control, enabling accurate machining, improved surface finish, energy efficiency, and adaptability to varying load and process requirements.

Our VFDs are used in the following machine tool applications:

- Spindle Drives

- Coolant Pumps

- Chip Conveyors

- Hydraulic Systems

- Tool Changers and Feed Motors

- Axis Drives (for non-servo applications)

Machine Tools

In machine tools, VFDs provide precise motor speed and torque control, enabling accurate machining, improved surface finish, energy efficiency, and adaptability to varying load and process requirements.

Our VFDs are used in the following machine tool applications:

- Spindle Drives

- Coolant Pumps

- Chip Conveyors

- Hydraulic Systems

- Tool Changers and Feed Motors

- Axis Drives (for non-servo applications)

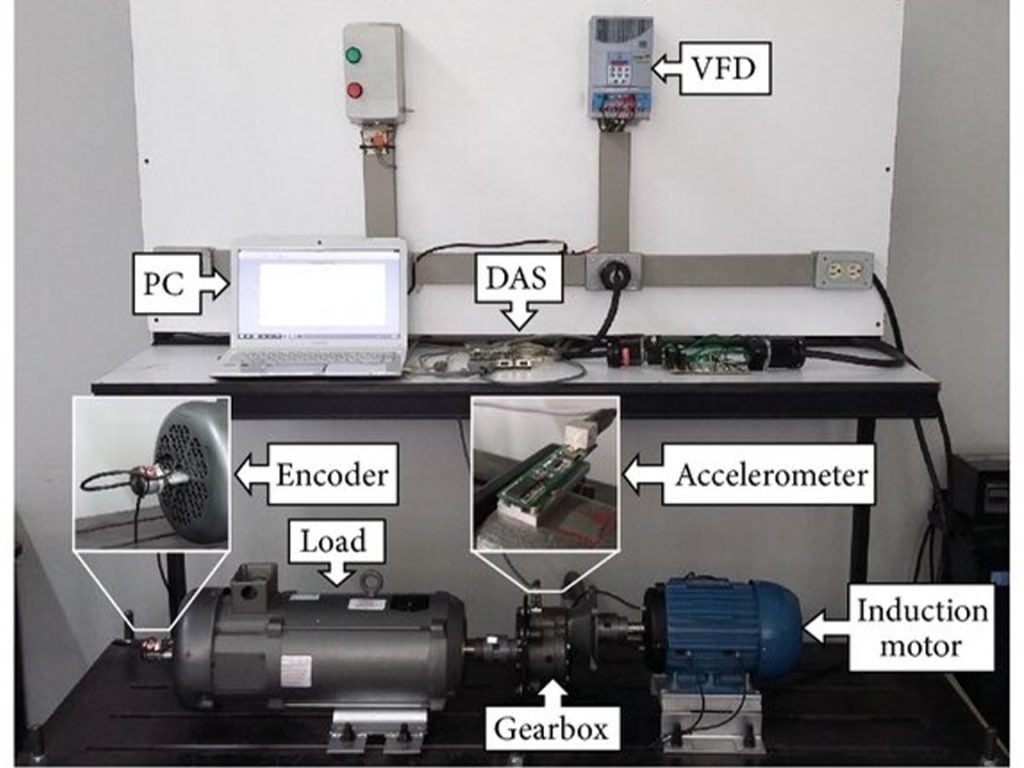

Test Bench

In test bench applications, VFDs provide precise and repeatable control of motor speed and torque, enabling accurate simulation of real-world conditions, data acquisition, and performance validation under variable load scenarios.

VFDs are required in the following test bench applications:

- Motor Testing Benches

- Gearbox and Transmission Test Benches

- Pump and Fan Test Benches

- Inverter/Drive Testing Benches